Just as spring follows winter see( spring woodfiring ), summer follows spring, I bet that was a revelation to 0.009 % of you.

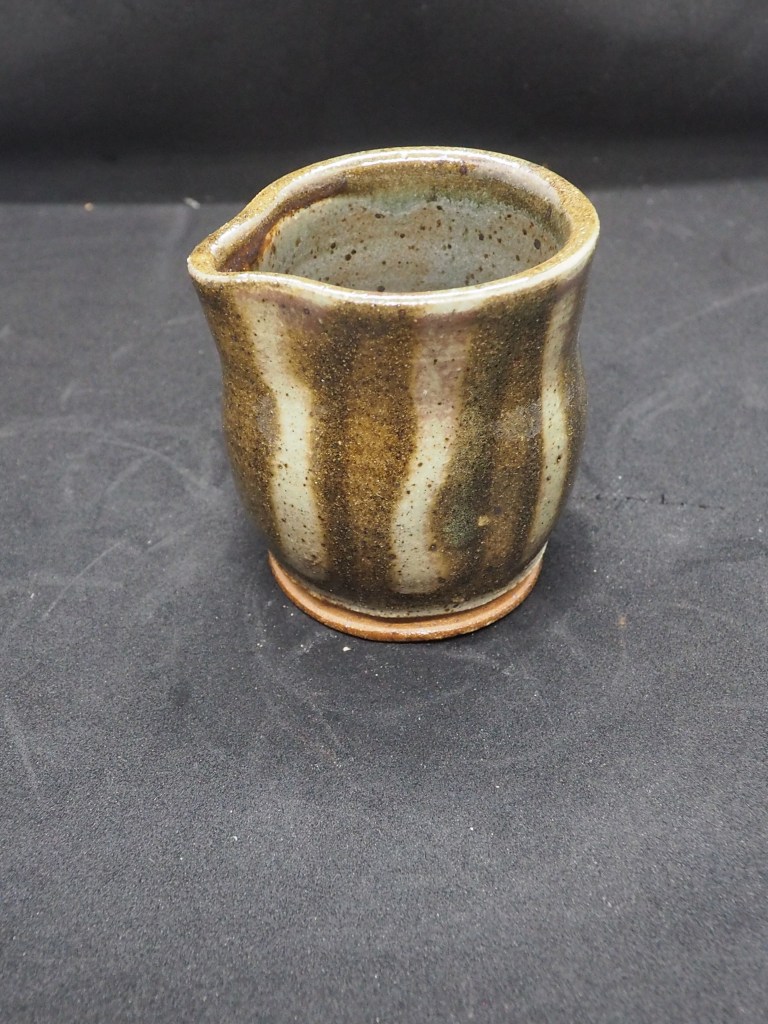

I had been making for this one since the spring, lots of bottles mugs, but nothing big. The middle of the kiln was filled with tiles needed to tile the wall behind the bin. Quite a bit of the ware had the local beach slip on them with a clear glaze. My new black slip was only used on one bottle, it was made with Knepp castle clay plus iron and manganese , I think it worked quite well.

The firing started easily with gas from the dregs of some cylinders, I hate exchanging cylinders that have gas in them, it is less noisy, less smokey and cleaner for the neighbours . I chose what turned out to be the hottest day of the year, on the safe side I was wearing long trews and long sleeves, just right for a hot day to be made hotter by a close encounter with the kiln of the wood firing type.

Wood was added at 700 and away we went, stoking with dead trees, mostly bought as waste wood from our local timber mill at Charlton in the south downs. Another visit soon .

All was going well until it reached 1100 when the thermo couple went on strike it laid down tools at 1150 and ceased work. Back to the cones, the colour didn’t look right either. After a few hours cone 8 started to indicate then 9 and 10 twitch, we rammed the fireboxes full and called it quits. Exhausted we jumped onto the barbeque to cool down.

I unpacked after 4 days when completely cool using an infrared gun to temperature check the pots through the spy holes, the thermo couple was still on strike for more money, £142 from Bath potters. Almost as expensive as my new filling in my tooth, 2nd molar upper left .

Next firing will be earthenware, which will be a challenge to stop it from reducing as you can see, the kiln likes to smoke .

are you going to be showing at the wood fair this year again?

LikeLike

Yes, we always look forward to Bentley, we will be taking some of the recent firing with us, if you introduce your self we may be able to provide you with a cup of tea and a chat. See you there . Tim

LikeLike